Guaranteed Quality with Precision Machining

Our precision machining services ensure quality parts on-time, every time.

01.

Prototype Machining

We specialize in making unique parts to exacting tolerances. If you need something made to fit your upcoming project, we are your shop.

02.

Production Machining

Need multiple units? See how we reduce your costs with innovative CNC production.

03.

In-House Inspection

Built-in trust: all parts are inspected in-process and finally before they are delivered, according to your standards.

Guaranteed Quality with Precision Machining

Our precision machining services ensure quality parts on-time, every time.

01.

Prototype Machining

We specialize in making unique parts to exacting tolerances. If you need something made to fit your upcoming project, we are your shop.

02.

Production Machining

Need multiple units? See how we reduce your costs with innovative CNC production.

03.

In-House Inspection

Built-in trust: all parts are inspected in-process and finally before they are delivered, according to your standards.

Our Experience Is Your Advantage

Selecting the right supplier can be difficult, so we work hard to stand out.

A Well-Equipped Precision Machine Shop

We have a shop floor full of CNC machines with highly varied capabilities in order to meet the needs of our customers. We also have a solid complement of manual machines to cover any gaps in our offering. Whether you need a simple part or a highly complex assembly, or anything in between, we have you covered.

Precision Machines:

- 2, 5-axis CNC milling centers

- 3, 4-axis CNC milling centers

- 1, 4-axis live-tooling CNC turning center

- 1, 3-axis live-tooling CNC turning center

- 1, 3-axis CNC mill

- 1, 2-axis CNC lathe

A Well-Experienced Collection of Materials

Our machinists have experience working with a large variety of metals, plastics, and other machinable materials. With our diverse experience it is likely we are already prepared to tackle your project, regardless of the material you choose.

Material Experience:

- Aluminum

- Stainless Steel

- Titanium

- Tungsten

- Precious metals

- Machinable Ceramics (Macor)

- Plastics

- Brass & Bronze

- Steels & Alloys

An Expert Team

With customer satisfaction as our main goal our team strives to deliver the best, every time. Our machinists work through your project with a focus on quality and attention to detail. Our office staff ensures prompt and accurate communication so you always know where your project stands.

Our Team Values:

- Excellence in the pursuit of precision

- Exceptional quality of finished parts

- A culture of collaboration and camaraderie

- Increased accuracy with model-driven toolpaths

- Reduced time with multi-axis machining

- Minimizing costs to customers

- Innovative material conservation

- Cross-trained expertise in milling and turning

Machine Capabilities of Our Shop

Concerned if we can manage your part? We are equipped to accommodate the following stock dimensions:

40" x 20" x 22"

Capacity of mill parts

16" DIA x 48" Long

Capacity of lathe parts

1,000 lbs

Weight limit of stock

±0.0002"

Repeatability of finished dimensions

Prototype Machining

Develop effective designs quickly and establish a high-quality product line:

Before manufacturing your product at scale, you may consider developing a series of prototypes. Successful companies understand this – and so do we.

Here at Yeamans Machine Shop, we help companies establish exceptional product lines by working within their timeline and producing prototypes to specification.

Depending on your industry and application, producing modern designs may be complex, costly and time consuming.

We make complex parts simple. By combining our seasoned knowledge of production and advanced operations, we can reduce the cost of developing new products for industrial partners like you in a fraction of the time.

Complexity shouldn’t mean costly. Next time you need to prototype a new design, let us show you how we would simplify the process and help you reduce the costs of modern manufacturing. Reach out to us today!

Precision

We sure can, single parts and small batches are our specialty.

Yes! Our team works with you to understand critical features, then develops an innovative approach to produce your part with the precision you need.

Typically yes, prototype parts are more expensive because a single part absorbs all of the setup and programming costs associated with the job. A production run allows that cost to be spread over multiple parts, getting you closer to only paying for the actual time spent machining each part.

Speed

We strive to meet tight deadlines with uncompromising quality. Call us at (505) 662-9313 to learn how soon you can expect delivery.

With 5 axes of motion available on a machine, we are able to machine features on multiple sides of a part in a single setup. This reduces handling time and increases accuracy for more complex parts.

Missing a deadline happens, and though we strive to avoid it sometimes things don’t work out. We track our on-time delivery percentage constantly, and it rarely drops below 95%.

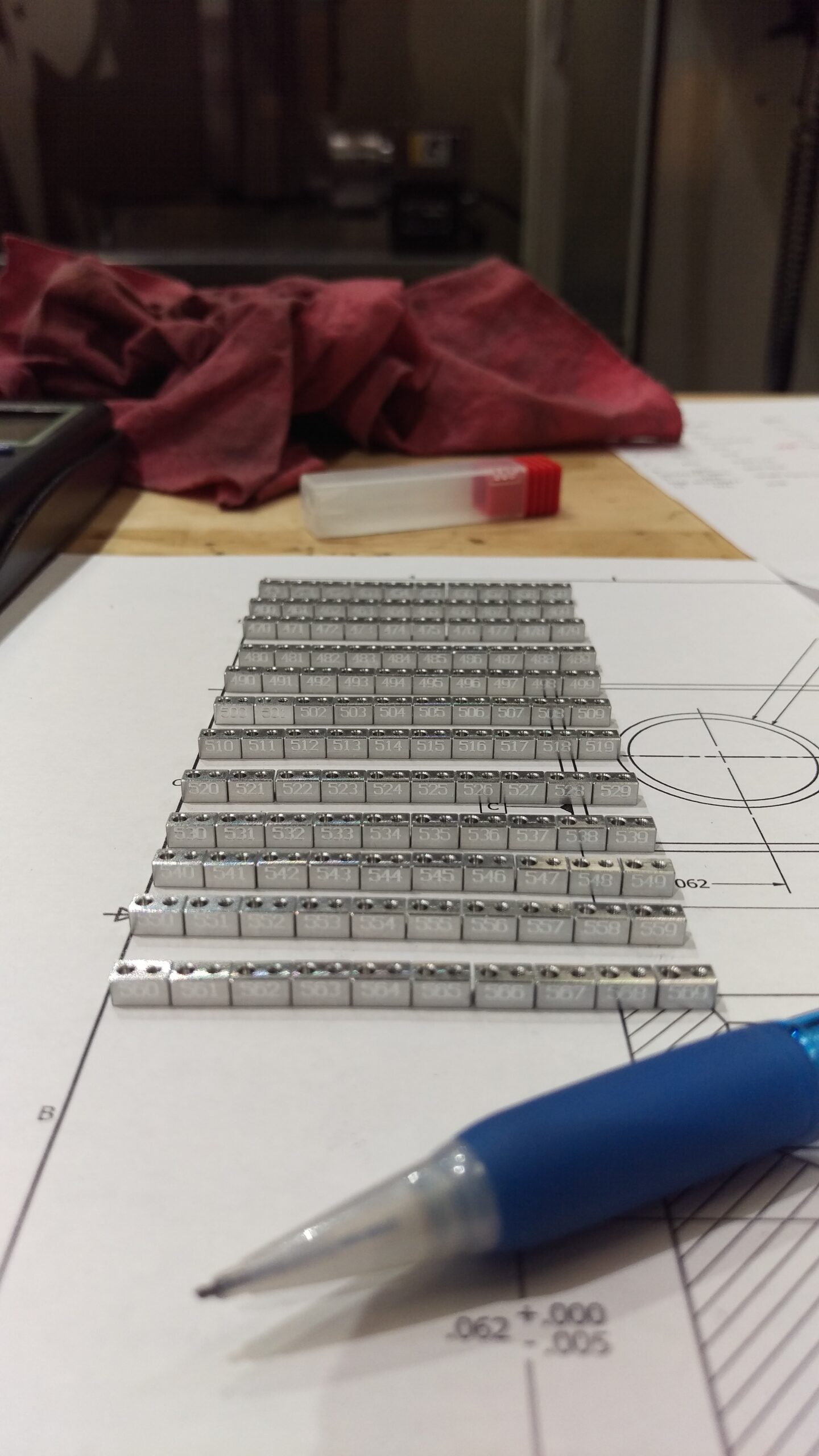

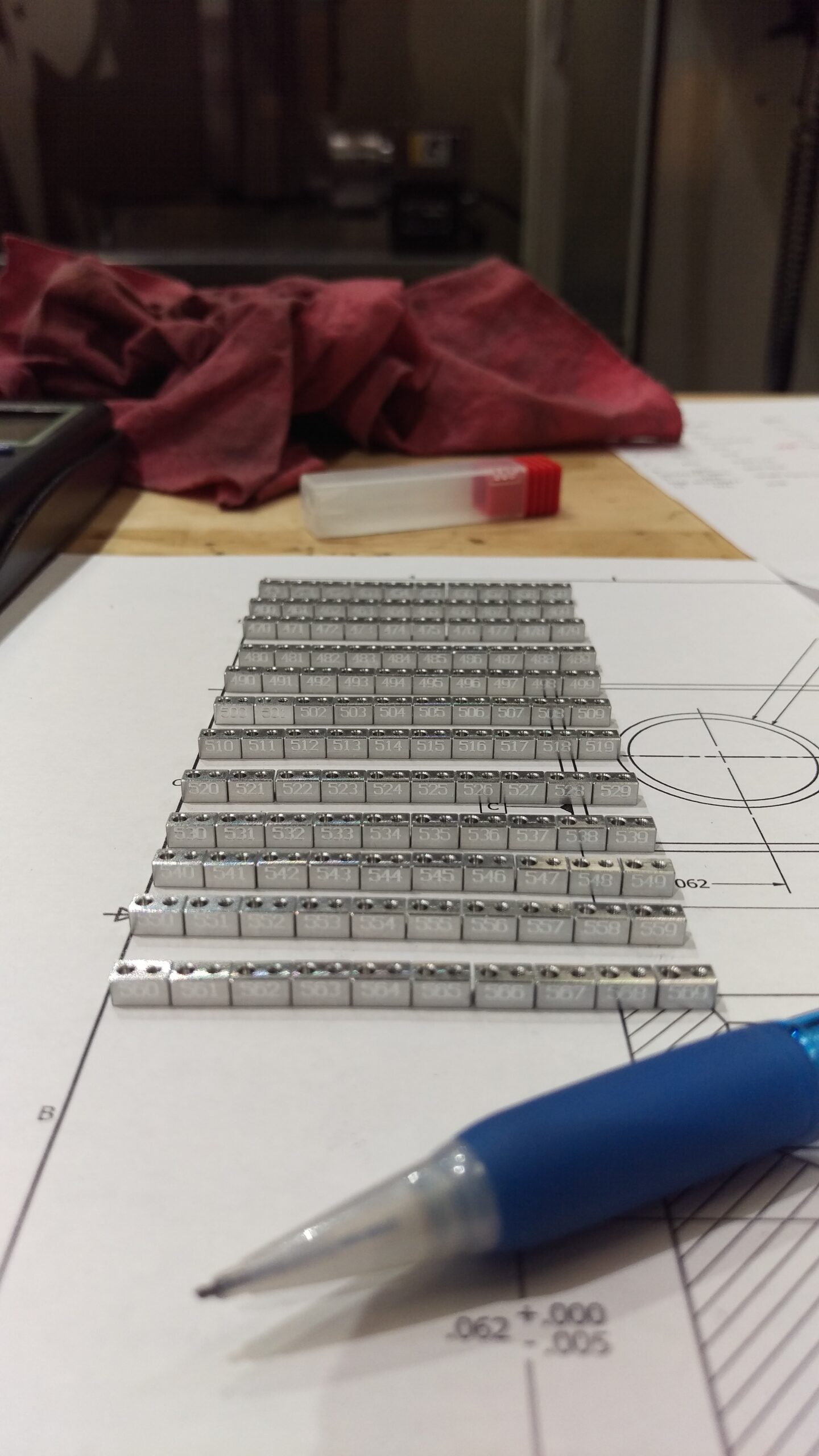

Production Machining

Fortify your supply chain and reduce unit costs:

Still facing supply chain issues with your inventory? Ready to scale your production? Or simply wanting to reduce your unit costs? Whatever your circumstance, we are prepared to meet your production needs.

Our network of trusted suppliers helps us mitigate supply chain issues, whether it is raw material, hardware, or tooling. Having a wide variety of suppliers keeps us ready to meet your needs.

With your production needs we stay focused on your timeline and budget. Our expert machinists utilize all of our machine capabilities to ensure your parts are produced efficiently and to your exacting standards.

Production Machining

Fortify your supply chain and reduce unit costs:

Still facing supply chain issues with your inventory? Ready to scale your production? Or simply wanting to reduce your unit costs? Whatever your circumstance, we are prepared to meet your production needs.

Our network of trusted suppliers helps us mitigate supply chain issues, whether it is raw material, hardware, or tooling. Having a wide variety of suppliers keeps us ready to meet your needs.

With your production needs we stay focused on your timeline and budget. Our expert machinists utilize all of our machine capabilities to ensure your parts are produced efficiently and to your exacting standards.

We further reduce your unit costs with our end-to-end services. In addition to our ability to produce at scale, we help you drive down unit costs with our secondary services like welding, surface treatment, heat treatment, labeling, assembly, kitting, packaging, storing and more. Explore our Secondary Services:

This means you can juggle fewer vendors and focus on serving your customers.

Ready to streamline your supply and widen your margins? Reach out to us today to learn how we can help!

Precision

Typically yes, production parts benefit from the ability to spread setup and programming costs across the entire run instead of only a single part.

Yes, while we specialize in complex prototypes, many of our customers return and ask us to make more. Once we have produced a single part, typically it is not difficult to adapt that process to the production of multiple units.

The first part of a production run is fully inspected to ensure quality. Critical features are checked throughout the run to ensure that quality is remaining consistent.

Volume

Generally, production means multiple parts will be made. We will always make just one part if that is what you need, but you will not benefit from the cost savings provided by production.

We sure can. Although large scale production is not what we are set up for, we usually have the capability to meet your needs, and if we cannot, we have trusted suppliers who can.

We would love to take on your recurring project! If you have a consistent need for parts we would love to discuss how our shop can best serve you.

Precision Inspection

We give you confidence with every part:

As an industry partner, we strive to meet your quality standards.

Backed by our ISO 9001:2015 certification our thorough inspection process means you can rest assured every part is delivered as designed.

By applying best practices throughout the machining process, we are able to repeatedly hold exceptional dimensional and geometric tolerances over extended runs. This equips us to produce high-precision components at scale for partners like you.

Tight tolerances are not uncommon for our partners who research and develop new technologies, like Los Alamos National Laboratory, and we continue to deliver what they need.

We meticulously maintain our inspection tools, and they are calibrated at regular intervals with standards traceable to NIST.

Precision

Yes. Our quality management system is designed around the requirements of ISO 9001 and maintained to ensure customer satisfaction, quality, and continuous improvement.

We use calibrated hand tools such as micrometers, indicators, gage blocks, and our granite surface plate to check the dimensions of your parts.

Yes, we do! We have a Zeiss CMM capable of measuring parts within a 20″x20″x20″ space to tolerances of .0001″.

Accountability

Yes, we can provide detailed inspection reports that tell you what each dimension actually measures so that you know exactly what you are getting.

All of the measuring tools we use are on a calibration schedule, and our machinists inspect each part in process using these tools. Each part is checked for dimensional accuracy before it is released to you.

Frequently Asked Questions

Typically yes, production parts benefit from the ability to spread setup and programming costs across the entire run instead of only a single part.

We consider the term prototype to imply that only one or a few parts are produced – typically as an initial phase before producing the units at scale. Production implies parts to be produced at scale.

No. We do not require minimum order quantities for parts.

No. All parts are produced according to their most effective and efficient approach.

All inspection tools are calibrated by a third party specialist, independent of Yeamans Machine Shop.

Please call us at (505) 662-9313, or complete the form below and your request will be processed within 24 hours.

Have Questions Now? Get Answers Now:

If you are ready to work with a reliable producer or simply have questions about a specific need, reach out to us today.

During business hours, we respond to phone calls within 2-hours and forms within 24-hours. Otherwise leave a message and we will return your call.

We look forward to speaking with you!

+1 (505) 662-9313

7am-5pm, Monday-Thursday

+1 (505) 662-9806 (fax)

yms@yeamansmachine.com

Request Your Quote Today

Have Questions Now? Get Answers Now:

If you are ready to work with a reliable producer or simply have questions about a specific need, reach out to us today.

During business hours, we respond to phone calls within 2-hours and forms within 24-hours. Otherwise leave a message and we will return your call.

We look forward to speaking with you!

+1 (505) 662-9313

7am-5pm, Monday-Thursday

+1 (505) 662-9806 (fax)

yms@yeamansmachine.com

Request Your Quote Today

Have Questions Now? Get Answers Now:

If you are ready to work with a reliable producer or simply have questions about a specific need, reach out to us today.

During business hours, we respond to phone calls within 2-hours and forms within 24-hours. Otherwise leave a message and we will return your call.

We look forward to speaking with you!

+1 (505) 662-9313

7am-5pm, Monday-Thursday

+1 (505) 662-9806 (fax)

yms@yeamansmachine.com